Today, manufacturers are facing many challenges. With increasing competition and diverse customer needs, companies need to continuously optimize production lines, improve production efficiency, and save production costs. Traditional manufacturing can no longer meet market demand. Therefore, it is imperative to transform and upgrade from traditional manufacturing to intelligent manufacturing. Intelligent Manufacturing (IM) is a new production method based on the deep integration of the latest information and communication technologies with advanced manufacturing technologies. It covers all aspects of manufacturing activities such as design, production, management, and service, and has self-perception, self-learning, self-decision-making, self-execution, and self-adaptation functions. Intelligent manufacturing takes intelligent factories as the carrier, focuses on the intelligence of key manufacturing links, is based on end-to-end data flow, and is supported by network interconnection.

Through intelligent manufacturing, companies can enjoy the following advantages:

Applications:

Factory Monitoring, including dashboards, KPI charts, and overall equipment efficiency;

Anomaly Detection;

Process control and functions with alarms;

Multi-image, multimedia, and equipment sound;

Supply Chain: demand forecasting, inventory optimization, supplier performance.

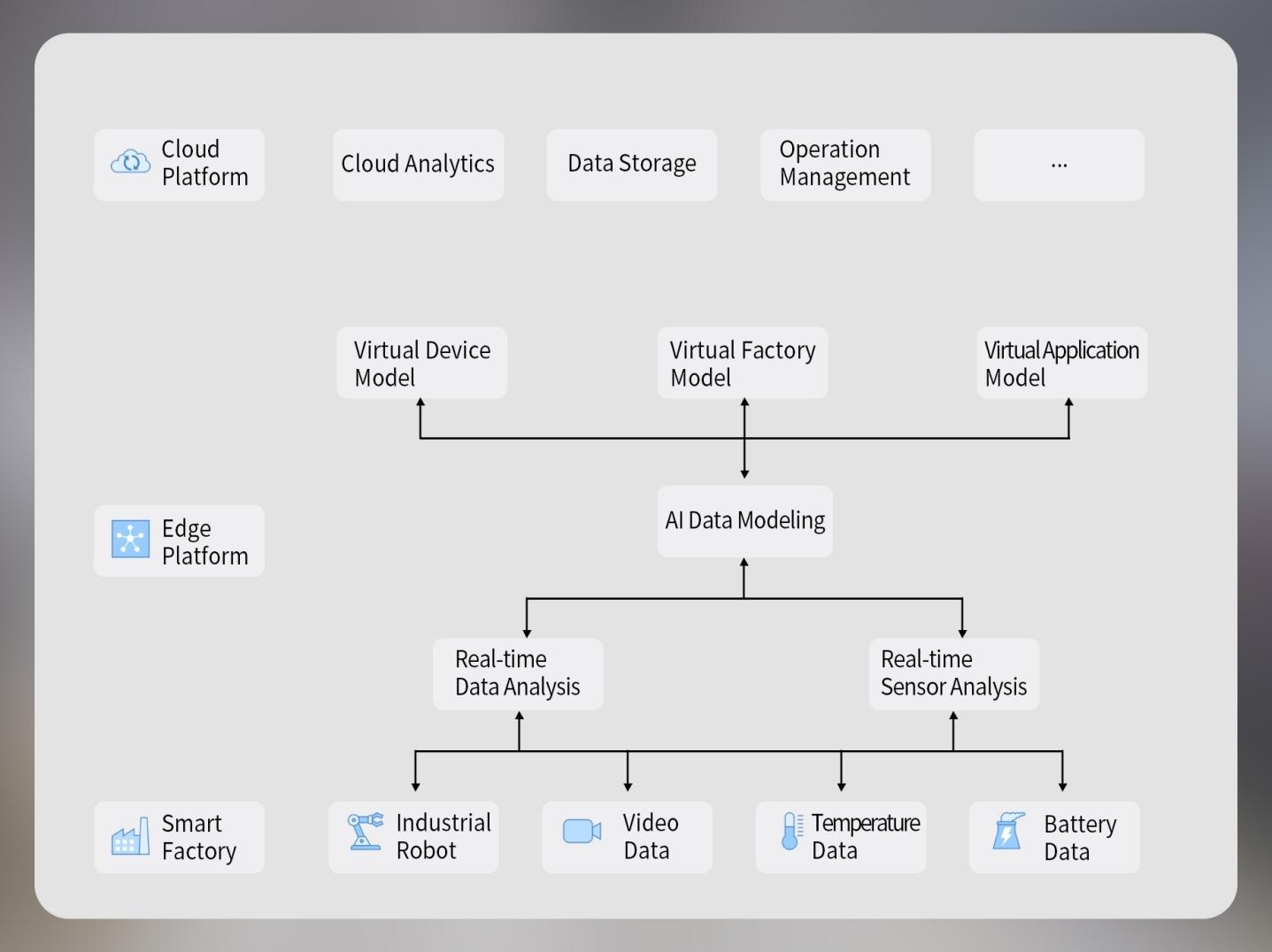

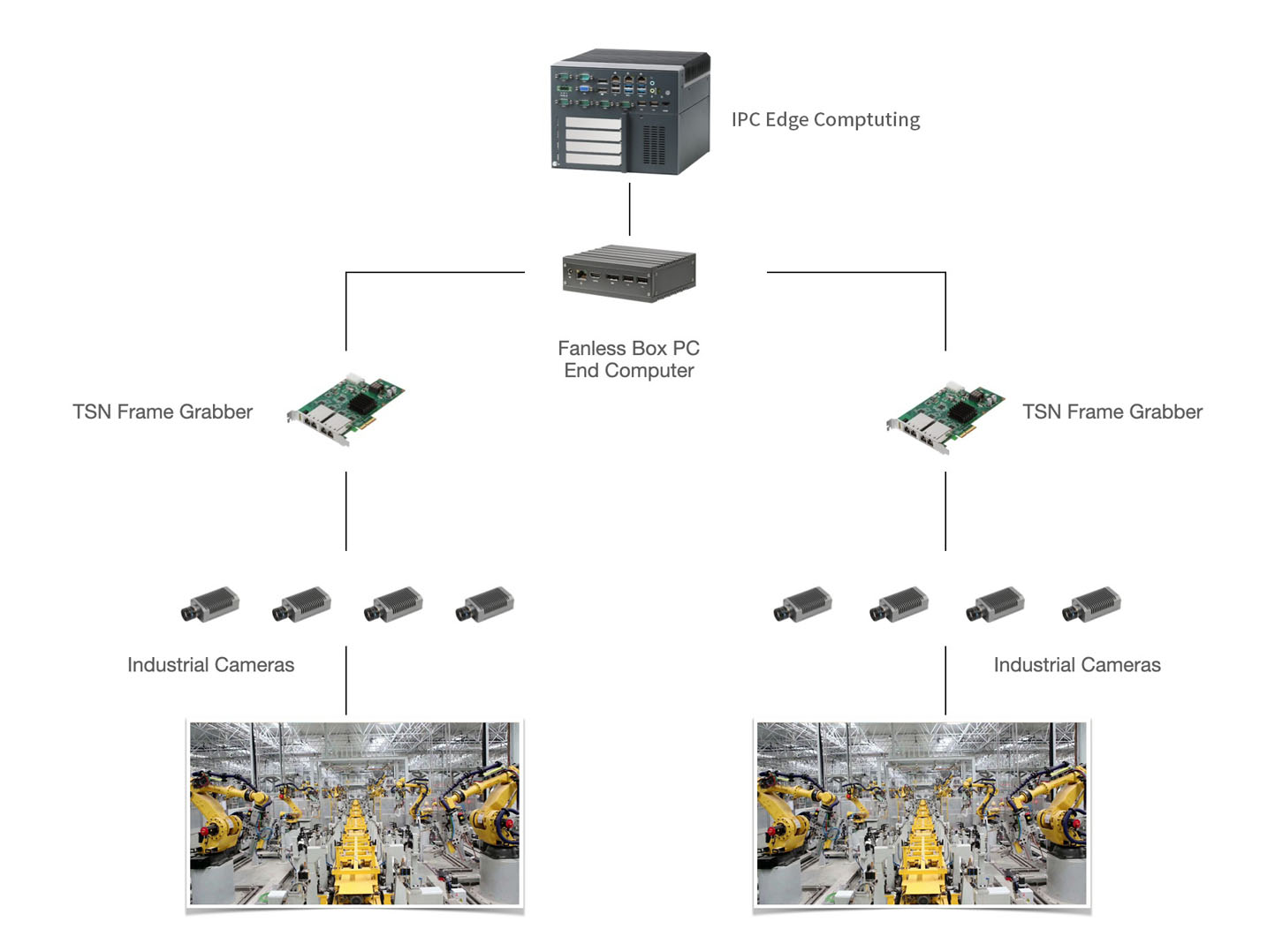

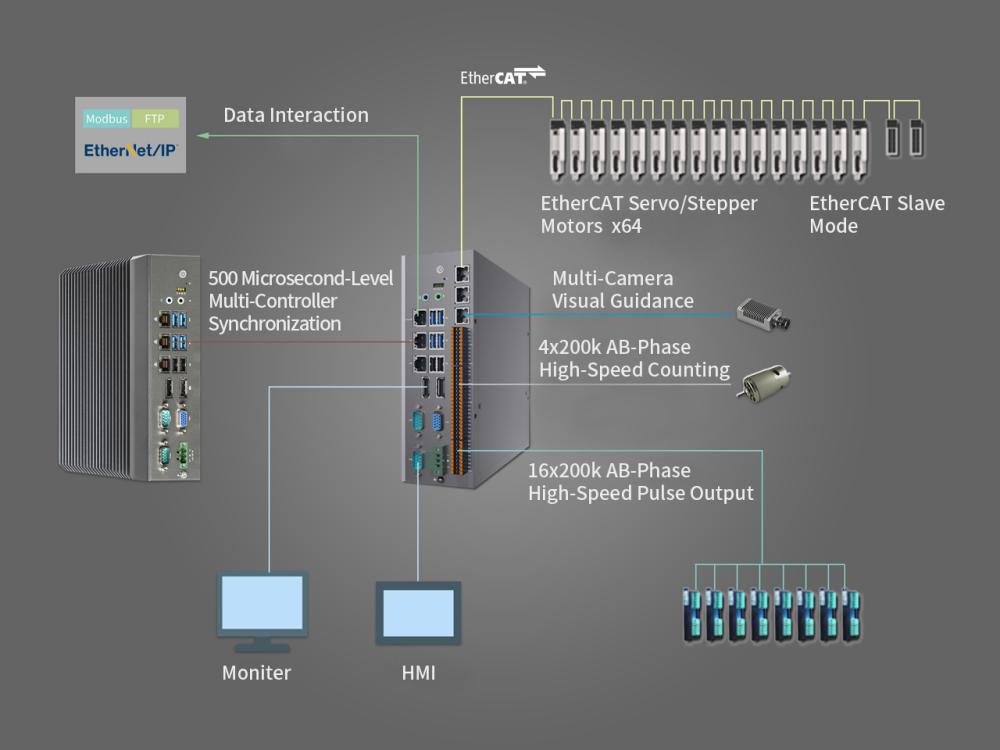

Intelligent users can swiftly construct an edge computing platform proximate to the factory’s IoT device data sources by utilizing IPC. This platform enables real-time data collection and analysis, enabling the creation of virtual data models. These models allow for the timely identification of production process risks and environmental changes. Furthermore, it optimizes equipment energy consumption, boosts production efficiency, and minimizes production costs. Factory users leverage sensors, industrial cameras, and edge-side IPCs for local data collection, seamlessly interacting with data via edge computing intelligent gateways. Edge-side IPCs perform real-time processing tasks such as data filtering and cleaning. Simultaneously, the edge computing platform operates on a TSN time-sensitive network, guaranteeing prompt data interaction. Additionally, factories can explore virtualization technology software modeling to implement industrial controllers, allowing for on-site production line control via the edge-side platform.

Machine Vision (MV) is a detection machine equipped with sensing vision instruments such as autofocus cameras or sensors. Optical detection instruments play a crucial role in it, which can be used to detect various product defects or used to judge and select objects. It is applied in automated production lines to calibrate and locate materials. As the most industrialized part of computer vision, it is mainly used in factory automation detection and robotics industries.

Nearly 80% of industrial vision systems are primarily used in detection, including improving production efficiency, controlling product quality during the production process, and collecting product information. Product classification and selection are also integrated into the detection function.

The vision system inspects products on the production line, determines whether they meet quality requirements, and generates corresponding signals to input into the host computer based on the results. Image acquisition devices include light sources, cameras, etc.; image processing devices include corresponding software and hardware systems; and output devices are related systems connected to the manufacturing process, including programmable controllers and alarm devices.

Applications

Automatic Optical Inspection (AOI)

Object and Image Recognition

Object Sorting

Measurement

Video/Surveillance Analysis

Saintway has developed products to assist enterprises in addressing real-time production issues, enabling cost reduction and efficiency enhancement based on edge computing and Industrial IoT . These solutions optimize equipment energy consumption, improve production efficiency, and ensure prompt data interaction through edge computing intelligent gateways.